| GRF |

HKUST |

615212

|

Prof Li, Zexiang/A geometric theory that unifies the

modeling, analysis and synthesis of parallel mechanisms for kinesiology,

constant velocity transmission and five-face machining |

| GRF |

HKUST |

615610

|

Prof Li, Zexiang/Motion Type Error and Optimal Design of Quotient Kinematics Machines |

| GRF |

HKUST |

616509

|

Prof Li, Zexiang/Geometric Synthesis and Dynamic Design of Quotient Kinematics Machines (QKMs) |

| GRF |

HKUST |

615808

|

Prof Li, Zexiang/Integrated Structure/Control Design of Lower Mobility Parallel Mechanisms for Semiconductor Applications |

| GRF |

HKUST |

616606

|

Prof Li, Zexiang/Tolerance-Based Motion Control System Design and Implementation |

| GRF |

HKUST |

616805

|

Prof Li, Zexiang/Parallel Manipulator Design for Optimal Workspace |

| GRF |

HKUST |

627604

|

Prof Li, Zexiang/A geometric theory for analysis and synthesis of sub-6 DoF parallel manipulators |

| GRF |

HKUST |

630103

|

Prof Li, Zexiang/Optimal parallel manipulator design as linear matrix inequality problems |

| GRF |

HKUST |

622602

|

Prof Li, Zexiang/Automatic generation of probing points for computer-aided set-up and inspection systems |

| GRF |

HKUST |

618701

|

Prof Li, Zexiang/Analysis, design and control of redundant parallel manipulators for industrial applications |

| GRF |

HKUST |

622199

|

Prof Li, Zexiang/Completion Of A Unified Control System Architecture For Multifingered Manipulation |

| GRF |

HKUST |

622098

|

Prof Li, Zexiang/Geometric algorithms for hybrid localization and tolerance verification |

| GRF |

HKUST |

668595

|

Prof Li, Zexiang/Intelligent manufacturing: Efficient algorithms for workpiece localization and dimensional inspection |

| GRF |

HKUST |

655594

|

Prof Li, Zexiang/Robot motion planning with nonholonomic constraints and applications to dextrous manipulation |

| GRF |

HKUST |

619393

|

Prof Li, Zexiang/Development of a task-level robotic hand manipulation system |

Compared with their serial counterparts, parallel manipulator architectures have potential advantages in terms of stiffness, inertia, speed/acceleration, and payload. On the other hand, they suffer from drawbacks such as limited workspace and complex kinematics and singularities. Over the last decade, significant advances have been achieved in understanding the kinematics and singularities of various parallel manipulator architectures and new design and actuation methods have been introduced to eliminate or reduce the effect of manipulator singularities. For serial manipulator designs, there is an important result that states that among all manipulators with six revolute (6R) joints and with a fixed manipulator length, the elbow manipulator and its inverse have optimal workspace. This explains in part the popularity of this architecture in a wide range of industrial applications. Numerous parallel manipulator architectures have been suggested in the literature. Also, in an effort to automate the solutions of the parallel manipulator design problem, we have recently proposed a geometric theory for synthesis of parallel manipulator architectures. Applications of this theory lead to an enormous number of possible parallel manipulator architectures for a given task. Supplementing our on-going work on mechanism synthesis, this project aims to study parallel manipulator architectures with good workspace performance and to apply this theory to the design of a parallel-structure-based 5-axis CNC router.

A CNC system designer is often faced with the challenge of designing the system so that partsare machined with desirable quality while maximizing the machine tool’s productivity. Here, quality is measured by the tolerance of the machined part and productivity by the velocity or feedrate of the machine tool. Current CNC system design suffers from two basic limitations. First, trajectories generated (or interpolated) by the CNC system do not explicitly address tolerance issue. The machine tool operator has to set feedrates based on his/her experience or general rules which are difficult to follow in specific machining situations. There is no guarantee that the tolerance will be maintained or the machine tool’s productivity be maximized. Second, trajectory tracking error instead of machining error (or tolerance error) is being minimized by the servo algorithm. This indirect approach means more expansive hardware are needed for a machine of the same accuracy. In this project, we propose a new concept of CNC system design: a tolerance-based motion control system. The system consists of two modules, a tolerance-based motion generation (TBMG) module and a tolerance-based motion control (TBMC) module. The TBMG module takes as input the desired level of tolerance and calculates the maximum permissible feedrate based on the trajectory, machine and the desired level of tolerance. The TBMC module minimizes directly the profiling (or tolerance) error, which is only a part of the contouring error, which in turn a part of the trajectory tracking error.

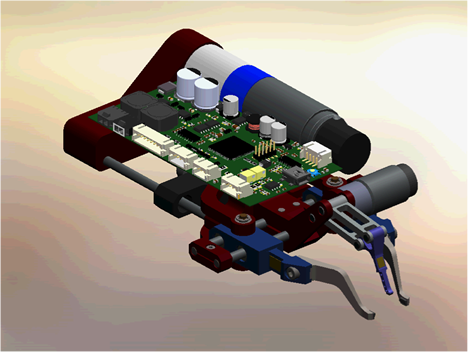

In semiconductor packaging, motion mechanisms are employed for applications ranging from wafer probing and handling, to die pick and place, to epoxy dispensing, and to wire bonding. Incessant consumer market demand for smaller, lower cost and higher quality electronic products places, more than ever, stringent requirement on the underlying mechanism' capabilities in terms of precision, speed, acceleration and even force control. Traditionally, semiconductor motion mechanisms are designed based on the open-chain or the stacked-axes construction method inherited from machine tool design. Recently, back-end equipment manufacturers are becoming increasingly interested in parallel-kinematics-based mechanisms (PKMs) because of their potential advantages in terms of low inertia, high acceleration and good force control capabilities. It is well known that the performance of a PKM is highly sensitive to its design parameters, including the structure and control parameters. This is especially so under high speed operation environment in which there are intricate interactions between structure and control. In this project, we propose an integrated structure/control design method for high performance PKMs intended for back-end semiconductor packaging applications. The project consists of studies of the following problems: (i) Translating the various process requirements into performance speciŘcations of the underlying mechanisms; (ii) Mechanism synthesis, using the diĆerential geometric tool we developed earlier, for the various lower mobility (2-, 3- and 4-DoF) semiconductor packaging processes; (iii) Dynamic modeling of flexible PKMs using finite element method (FFM); (vi) formulation and solution of the optimal structure/control design problem; (v) development of a 2-DoF PKM prototype for wire-bonding applications, using the proposed design methodology.

In robotics, mechanism research is mainly concerned with studies of serial kinematics machines (SKMs) and parallel kinematics machines (PKMs), including their synthesis, kinematics and designs. This is largely due to the fact that these machines, aside from their relative importance, have unique and well defined kinematic structures to permit systematic studies of their properties and applications. Machines that do not fall into these two categories are usually lumped into a class called hybrid kinematics machines (HKMs) and are rarely (or much less) treated, severely limiting their usages in real applications. In an early research, we identified a fourth type of kinematics machines, called Quotient Kinematics Machines (QKM), with unique and well defined structures. A QKM realizes a desired motion described often by a Lie subgroup G of the special Euclidean group SE(3) through the coordinated motion of two motion modules, one realizing a subgroup H of G, and another a complement of H in G, denoted by {G/H}. It is also capable of realizing more complex submanifold motions such as that of five-axis machines. Most importantly, a QKM has several critical advantages over its serial or parallel counterparts: (i) simpler designs leading to better rigidity, higher reliability and lower cost; (ii) better suited for modular and reconfigurable designs; (iii) ability to retain the advantages of SKM and PKM while avoiding their shortfalls; and (iv) richer topological structures. As such, QKMs have been increasingly applied to demanding industry applications such as semiconductor packaging and five-axis machining. In this project, we aim to complete a unified theory for QKM synthesis and design and to validate this theory through the development of a novel QKM prototype for five-face machining. Through this research, we expect that QKM technologies will be more readily available for demanding applications and mechanism research will be more complete, with a well developed theory for an important new class of machines.

A quotient kinematics machine (QKM) consists of a pair of mechanisms, often referred to as a left and a right hand (or module), that act in unison. The set of relative displacements between the two QKM hands determine the motion type of the QKM, which could be a Lie subgroup, a submanifold or a quotient space of SE(3), the special Euclidean group of R^3. A QKM has several important performance advantages over its purely serial or parallel counterparts, such as simpler kinematic structures and better rigidity, and is better suited for modular and reconfigurable designs. Consequently, QKMs are increasingly being utilized in applications demanding high speed and high accuracy at the same time, e.g., those associated with semiconductor packaging and high speed machining. The overall positioning accuracy and thus the performance of a QKM is critically dependent not only on the accuracy of each hand but also on the coordination and compatibility between the two. Thus, a holistic approach is needed for the topology selection, dimension optimization, calibration, and control of the two QKM modules, using a common or a consistent set of objective function(s). In this project, we propose to study and characterize a QKM's positioning error that arises from joint clearance and link deflections. We develop geometric and physical interpretations for the motion type error and the internal error obtained by projecting the positioning error to two complementary subspaces. We develop efficient algorithms for computing the bounds of these error terms over a prescribed workspace. Then we explore the use of the motion type error for topology selection and dimension optimization, and the internal error for calibration, coordinated motion generation and control for the QKM modules. Finally, we evaluate the designs of QKM using the motion type error as the performance index and apply the proposed design concept to the design of a QKM intended for LED die bonding.

The purpose of the proposed project is to study and classify all exponential submanifolds

of interest, to apply the geometric properties of these submanifolds to model and analyze

mechanisms developed for the aforementioned applications, to complete a geometric theory

for parallel mechanism analysis and synthesis, and to synthesize novel mechanisms for fiveface

machining and high performance CV transmissions.